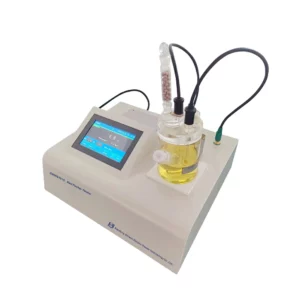

A Karl Fischer titrator is an analytical instrument used to determine the moisture content in various substances, particularly in liquids and solid materials. In the context of predictive maintenance strategies, the role of a Karl Fischer titrator is to assess and monitor the moisture levels in critical components or materials within industrial equipment.

Here’s how it contributes to predictive maintenance:

- Early Detection of Moisture-Related Issues: Moisture ingress can lead to corrosion, degradation of lubricants, insulation breakdown, and other forms of damage to machinery and equipment. By regularly measuring moisture levels using a Karl Fischer titrator, maintenance personnel can detect moisture-related issues at an early stage, allowing for timely intervention before significant damage occurs.

- Prevention of Equipment Failure: Excessive moisture content can compromise the performance and reliability of machinery and equipment. By monitoring moisture levels, predictive maintenance strategies aim to prevent equipment failure caused by moisture-induced corrosion, insulation breakdown, or lubricant degradation. Early detection and mitigation of moisture-related issues help extend the lifespan of equipment and minimize costly downtime.

- Optimization of Maintenance Schedules: Predictive maintenance involves scheduling maintenance activities based on the actual condition of equipment rather than predetermined intervals. By continuously monitoring moisture levels with a Karl Fischer titrator, maintenance schedules can be optimized to address moisture-related issues precisely when needed, minimizing unnecessary maintenance and maximizing equipment uptime.

- Identification of Root Causes: Karl Fischer titration provides quantitative data on moisture levels, allowing maintenance personnel to identify the root causes of moisture ingress or accumulation. This information can help pinpoint sources of leaks, inadequate sealing, or environmental conditions contributing to moisture-related problems, enabling targeted corrective actions to be taken.

- Verification of Drying Processes: In industries where moisture-sensitive materials or processes are involved, such as pharmaceuticals, food production, or chemical manufacturing, Karl Fischer titration can be used to verify the effectiveness of drying processes. By ensuring that moisture levels are within specified limits, predictive maintenance strategies help maintain product quality, compliance with regulations, and operational efficiency.

- Integration with Condition Monitoring Systems: Karl Fischer titration data can be integrated with condition monitoring systems or maintenance management software for comprehensive asset management. By combining moisture level data with other predictive maintenance indicators, such as vibration analysis or thermography, maintenance personnel can gain a holistic view of equipment health and make informed decisions regarding maintenance priorities and resource allocation.

Overall, the role of a Karl Fischer titrator in predictive maintenance strategies is to provide accurate and timely information about moisture levels in critical components or materials, enabling proactive measures to be taken to prevent equipment failure, optimize maintenance schedules, and ensure operational reliability.